B&T Technologies Experts in Processing Food Waste to Animal Feed

About B&T

B&T Technologies and its predecessor companies have been deeply involved with the research and development of sustainable process technologies since 1989 to create high quality animal feed, pet food and human food ingredients. Instead of using expensive or unavailable virgin grains as the starting material, B&T’s sustainable production utilizes food waste that otherwise would have ended in landfill. The B&T production materials are sourced either from unsold or unused factory food waste (pre-consumer food waste) or food that has reached the market but not consumed (post-consumer food waste).

To date, B&T has manufactured twenty-seven (27) Food Waste to Animal Feed Processing Plants worldwide. Experience from each of these projects provides our customers with the most advanced technology for producing Animal Feed, Pet Food and Human Food ingredients derived from unsold/unused food.

Unique Technology

Food Waste Collection

Plastic totes or bulk collection using special trucks

Foreign Object Removal

Low-skilled labor to sort/remove foreign objects from wet food waste – traditional pick line conveyor shown. Low-skilled labor can process 1-2 wet tons/hr/person

Mixing / Texturizing

Mix wet and dry materials to texturize (adjust moisture of homogenous mixture to pelletize)

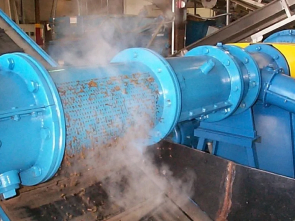

Pelletizing

Low pressure extrusion process to form long spaghetti strands – uniform shape for uniform drying

Fluid-Bed Drying

Hot gasses (300-350 ℉ / 149-177 ℃) at gas upflow velocities of 13-15 ft/s (4.0-4.6 m/s) creates high evaporative drying rates. The drying time is 7-9 minutes to reach 10% moisture. The surface of the pellet strand remains at the wet bulb temperature of the gas (165-175 ℉ / 74-79 ℃), so the pellet remains below its ignition point and does not burn.

Conditioning

After drying, pellets are heat soaked for 20-22 minutes at 210-212 °F / 99-100 ℃. Conditioning reduces pathogens by 99.99% and meets USDA requirements for animal feed derived from human food.

High Efficiency Cyclones

The exhaust gas from the fluid-bed dryer and cooler contains particulate matter (PM) that represents up to 1% of the total mass flow rate. The particles that escape in the exhaust gas have a relatively large average particle size and are easily captured with high efficiency dust collectors (cyclones).

Projects

| Year Operational | Technology | Location | Customer | Size, Wet Tons/day |

|---|---|---|---|---|

| 2025 | Pellet/Powder | Amman, Jordan | Specialty Modern Feed | 350 |

| 2019 | Powder | Mt. Prospect, IL USA | Cereal Byproducts | 150 |

| 2017 | Pellet | N. Grafton, MA USA | FeedBack Earth, Inc. | 350 |

| 2004 | Pellet | Hongseong-gun S. Korea | NutraKorea | 300 |

| 2000 | Pellet | Orlando, FL USA | NurtraCycle | 100 |

| 1999 | Pellet | Oshkosh, WI USA | NurtraCycle | 100 |

| 1999 | Pellet | Somerset, NJ USA | Envirofeed, Inc. | 200 |

| 1999 | Pellet | Gadsden, CA USA | Purina Feeds | 400 |

| 1998 | Pellet | S. Charleston, OH USA | Purina Feeds | 400 |

| 1997 | Powder | Truman, MN USA | TRE Enterprises, Inc. | 100 |

| 1996 | Pellet | Raleigh, NC USA | NCSU College of Ag | 100 |

| 1996 | Pellet | Clermont, FL USA | NutriFeed, Inc. | 50 |

Our Team

William H. Moss

Founder/Owner

Bill has been a designer, developer and operator of sustainable food and feed plants since 2000. He has built and operated processing plants in three continents. These processing plants take in unsold/unused food to produce dry/dehydrated pellets or powder which can be used as ingredients in feed and food products.

Bill began his career as a consulting environmental engineer with Dalton-Dalton Newport (now URS) where he rose to chief environmental engineer. He became an engineering manager in industrial automation with ABB (Swiss/Swedish multinational engineering company) and then a marketing executive with McDermott International before becoming President of Nutracycle Inc., predecessor company to B&T Technologies LLC.

Bill has a BS and MS degree in chemical engineering and an Executive MBA, all from Case Western Reserve University. He was an adjunct professor in chemical engineering at Case Western Reserve University 1997-2002 and is the inventor for 25 patents.

Anthony R Morgenthau

Founder/Managing Director

Mr. Morgenthau spent more than 50 years in investment banking and corporate finance. He began his career in 1969 as a registered stockbroker with the brokerage firm Francis I DuPont, specializing in private placements in oil and gas and real estate. In 1972 he founded Morgenthau & Associates, a Baltimore based NASD member Broker-Dealer specializing in private placements of oil and gas operations, real estate and private equity, and ran the firm until 2001.

He also serves as the President of the General Partner for ARM Holdings, LP. He brings more than five decades of proven success in the areas of investment banking, tax and estate planning, oil and gas exploration, real estate investing and venture funding of early-stage companies.

In 2000 pursuing his wife’s interest in car racing they formed BAM Racing LLC which started as a part time ARCA Team and later expanded into a NASCAR Cup team with 100 employees. It was during this time that Mr. and Mrs. Morgenthau became interested in the environment, becoming the primary investors in Nutracyle, LLC, which became B&T Technologies, LLC.

Mr. Morgenthau attended Culver Military Academy, Culver, Indiana from 1960 to 1964. Upon graduating, he attended Westminster College in Fulton, MO from 1964 to 1968, receiving a Bachelor of Arts degree.

Sumit Pasricha

Managing Director and Head of MENA & India

Sumit has extensive background building companies, raising capital, and leading successful sales efforts for a number of industries including fintech, electric vehicles, banking, and sustainable corporate finance. He has extensive background building companies, raising capital, and leading successful sales efforts for a number of industries including fintech, electric vehicles, banking, and sustainable corporate finance.

For the past two decades, Mr.Pasricha has been leading the Financial services in multinational companies. Since the beginning of 2021, he has been running his own Consultancy Practice (Avant Garde Advisors) with emphasis on Project Finance, M&A, Capital Raise for both Conventional as well as Fintech’s. He also represents disruptive clean energy company Ideanomics Inc (NASDAQ listed) for the Middle East helping it to roll out its commercial

EV and charging solutions for fleet operators into the region. He is presently leading the business development efforts for B&T Technologies in the Middle East, North Africa, India and Europe.

Mr.Pasricha started his banking career with HSBC in Mumbai, India, in wholesale banking, instantly progressing with his expertise and passion, he was selected to take an upgraded role in Bahrain, which brought him to the Middle East.

He is a Chartered Accountant (ICAI) by profession and holds a Master of Science (Financial Services) from the University of Manchester.

Elizabeth Ann Coulter-Morgenthau

Founder/Director

For decades, Mrs. Morgenthau has been very active with fund raising and sitting on the boards of several charities, in addition to playing a key role in helping her husband establish his NASD investment banking business, Morgenthau & Associates. Her family’s business, Coulter Corp., was sold in 1997 for over one billion dollars.

In 2001 she established BAM Racing, which grew from a part time ARCA Race Team to a full time NASCAR Cup Team. Elizabeth supervised the management of the team with the help of Eddie Jones, the team’s manager until 2010 due to lack of sponsorship. The friendships and business relationships that were made during this time still exist today. “Beth Ann”, as she is known, while owning the team became friends with one of the sons of her childhood racing hero, AJ Foyt.

As an entrepreneur and investor, Beth Ann has been involved in all of Anthony Morgenthau’s investments, providing a woman’s point of view on the management and objectives of those investments.

Contact us

B&T Technologies LLC

9130 NW 53rd St, Coral Springs, FL 33067

+1 954 649-0377 Contact William Moss, President bill@BandTtech.com

Normal Business Hours East Coast USA